Copy of Article Text Below

.....gearbox is made very rigid, so that it gives a pleasantly precise change, then it will transmit noise back from the engine compartment to the cockpit. Make it sufficiently flexible to avoid any such noise transmission and the gear change suffers. Only by much trial and error was an acceptable compromise eventually arrived at.

As development progressed on both sides of the North Sea, the Dunton suspension and chassis people went from drum to disc brakes and also reduced the wheel size from 13 in to 12 in. Braking invariably poses a problem with front wheel drive since, with much of the weight concentrated forward, it is easy to overbrake the rear wheels in an emergency so that they lock up and the tail slides sideways. Obtaining just the right amount of brake balance is difficult on a small car in which there is such a difference between the load on the rear wheels when the car is carrying four passengers and their luggage, and when only the driver is aboard. Ford experimented with braking ratios and linings, and have now come to the conclusion that ultra smooth finish brake drums are vital if the shoes are not to pick up during an emergency stop.

Dunton were also responsible for some drastic modifications to the front and rear suspension. During the period when the project was transferred to Dearborn, the engineers there had developed a most ingenious front suspension employing U shaped torsion bars which were simultaneously the springs, the anti roll bars and the radius arms. This ingeniously simple suspension not only cost less than an orthodox system to manufacture, it also weighed nine pounds less and was so compact it enabled the spare wheel to be carried under the bonnet, leaving that much more room in the boot. Alas, the torsion bars proved impossible to manufacture in quantity to the required, very precise dimensions, so were replaced by a normal MacPherson strut system and the spare wheel relegated to the boot again.

The rear suspension, top, posed problems in its original, simple form, proving too soft and allowing the tail to drift out, so was replaced by the present ingenious system with a dead rear axle located by a Panhard rod, two lower radius arms and short straps attached to the dampers instead of upper radius arms.

Even after Ford's top people had finally chosen the Fiestas's shape a great deal of work by feasibility engineers was required, for the most influential of all the prototypes was the one known as the Ghia Wolf from the Turin studios. But turning this body from a one-off with its skin carefully formed by hand into a body to be built by the million was a long, painstaking process.

Crash testing as prototypes were pulled against the Merkenich concrete wall taught other lessons. The front structure was stiffened and the battery cable re-routed so that it no longer passed below the engine, for when the engine moved on its mounting at the moment of impact it sometimes cut the cable with the consequent risk of fire. It was also found that the frontal impact could jam the starter.....

Captions -

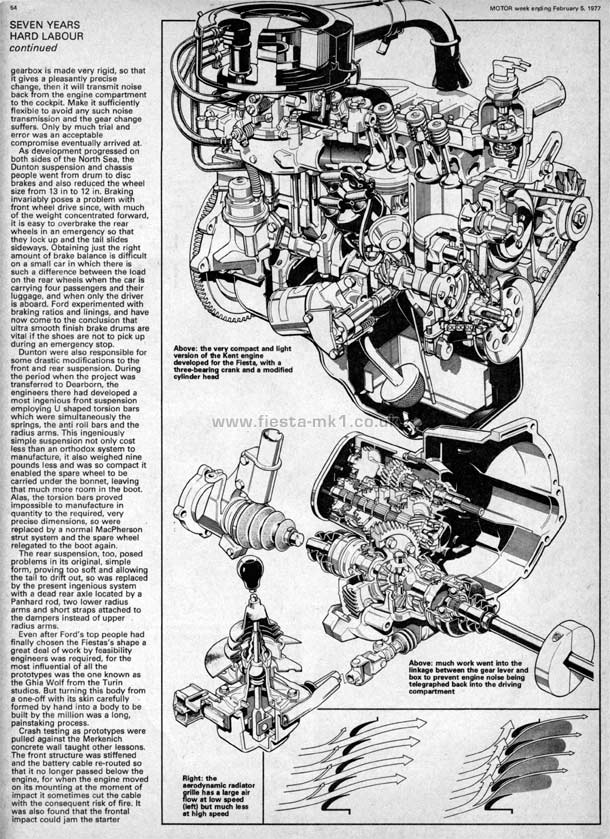

Middle - Above: the very compact and light version of the Kent engine developed for the Fiesta, with a three-bearing crank and a modified cylinder head

Bottom-Left - Right: the aerodynamic radiator grille has a large air flow at low speed (left) but much less at high speed

Bottom-Right - Above: much work went into the linkage between the gear lever and box to prevent engine noise being telegraphed back into the driving compartment

|