Copy of Article Text Below

.....locking one on the differential action, rather than the reaction to torque generated in most mechanical differentials with a limited slip action. In testing it was found that a mechanically limited differential was fine on tarmac, but on the loose the car became all but undriveable through snatching violently from side to side. With the Ferguson layout the limiting action starts as soon as one wheel starts to spin. This does not happen on fast tarmac use - "you would be better off with the normal differential rather than a mechanical limited slip on the loose," Meade comments dryly - but when the differential is in action they reckon they can get up to 85 per cent, mechanical efficiency. "The closest parallel I can think of is a torque converter," says Meade. From a Ferguson viewpoint the design is totally new for this Ford application, but the principles had been established by their 4-WD development.

Testing with the Ferguson differential layout was underway by August/September of 1978. The body that appeared as DHJ 50oT for Roger Clark had actually completed a lot of work before it wore that registration plate, for the Ford facilities away from public eyes were extensively used. As per Ford's normal practice in the UK, the bodyshell was prepared by Maurice Gomm at Woking. The j-door hatchback received careful seam-welding, but the old Escort trick of re-mounting the rear shock absorbers in turrets is history on the Fiesta. The dampers remain in the production position and carry out the production job of locating the axle against modest torque forces through a strap that stretches over the top of the production dead axle and links down to the axle itself. Ugly, but effective enough for tarmac at present.

However, I should hate readers to think that Boreham/Gomm ingenuity is to die with the Escort. Though the Fiesta looks a lot simpler than the F.scort, there are aluminium wheel arches and a i6-point roll cage to consider. The interior cage picks up in the rear damper top-mounting area, also covers the centre (B-post) with side location bolts and runs down the inside of the front screen, culminating at the dashboard. It would be tempting to run the cage on through to the front suspension mounting points, but that is possible future development. At present those front mounting points are just thicker and carefully welded.

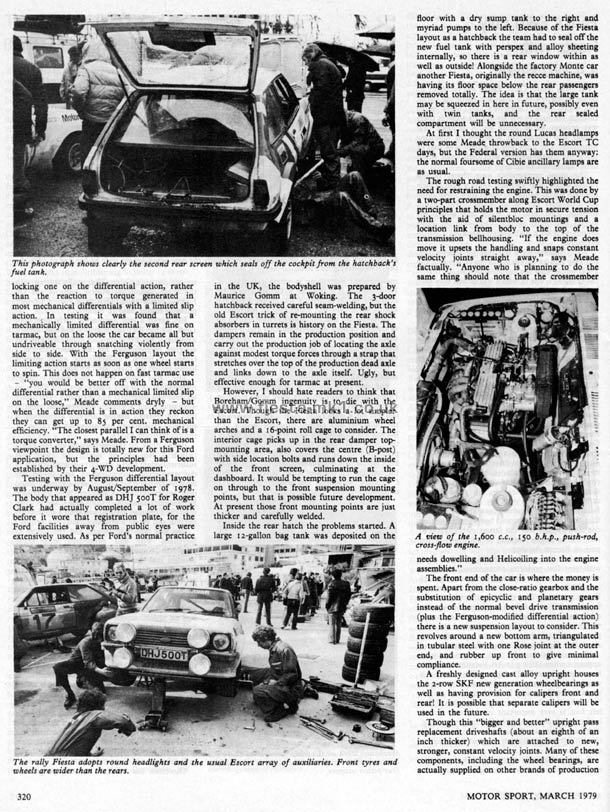

Inside the rear hatch the problems started. A large i2-gallon bag tank was deposited on the floor with a dry sump tank to the right and myriad pumps to the left. Because of the Fiesta layout as a hatchback the team had to seal off the new fuel tank with perspex and alloy sheeting internally, so there is a rear window within as well as outside! Alongside the factory Monte car another Fiesta, originally the recce machine, was having its floor space below the rear passengers removed totally. The idea is that the large tank may be squeezed in here in future, possibly even with twin tanks, and the rear sealed compartment will be unnecessary.

At first I thought the round Lucas headlamps were some Meade throwback to the Escort TC days, but the Federal version has them anyway: the normal foursome of Cibie ancillary lamps are as usual.

The rough road testing swiftly highlighted the need for restraining the engine. This was done by a two-part crossmember along Escort World Cup principles that holds the motor in secure tension with the aid of silentbloc mountings and a location link from body to the top of the transmission bellhousing. "If the engine does move it upsets the handling and snaps constant velocity joints straight away," says Meade factually. "Anyone who is planning to do the same thing should note that the crossmember needs dowelling and Helicoiling into the engine assemblies."

The front end of the car is where the money is spent. Apart from the close-ratio gearbox and the substitution of epicyclic and planetary gears instead of the normal bevel drive transmission (plus the Ferguson-modified differential action) there is a new suspension layout to consider. This revolves around a new bottom arm, triangulated in tubular steel with one Rose joint at the outer end, and rubber up front to give minimal compliance.

A freshly designed cast alloy upright houses the 2-row SKF new generation wheelbearings as well as having provision for calipers front and rear! It is possible that separate calipers will be used in the future.

Though this "bigger and better" upright pass replacement driveshafts (about an eighth of an inch thicker) which are attached to new, stronger, constant velocity joints. Many of these components, including the wheel bearings, are actually supplied on other brands of production.....

Captions -

Top-Left - This photograph shows clearly the second rear screen which seals off the cockpit from the hatchback's fuel tank.

Middle-Right - A view of the 1,600 c.c., 150 b.h.p., push-rod, cross-flow engine.

Bottom-Left - The rally Fiesta adopts round headlights and the usual Escort array of auxiliaries. Front tyres and wheels are wider than the rears.

|